Desktop lab or box scanners have evolved to the stage where all scanners in the same class are more similar than they are different from a performance point of view, but there are still a number of differences between them when the overall package is considered.

It’s important to first understand that some scanner products come integrated with the CAD software and some don’t. In Canada you have the choice of four complete dental CAD systems: Dental Wings, 3Shape, inLab and Exocad. Exocad also exists as a private-label version for systems like Zirkon Zahn, Amann Girrbach and Nobel Biocare. The only CAD software that is typically sold separately from the lab scanner is Exocad, in it’s branded version. For all the other CAD solutions the CAD is deeply integrated with the scanner hardware solution. More in this later.

LAB SCANNERS ARE DIFFERENTIATED ALONG THE FOLLOWING LINES:

Light source, Accuracy, Speed, Capacities, Build quality, Scan file type, Software functionality, Annual license fees, Overall cost and, as mentioned above, How deeply they’re tied to the CAD solution.

LIGHT SOURCE:

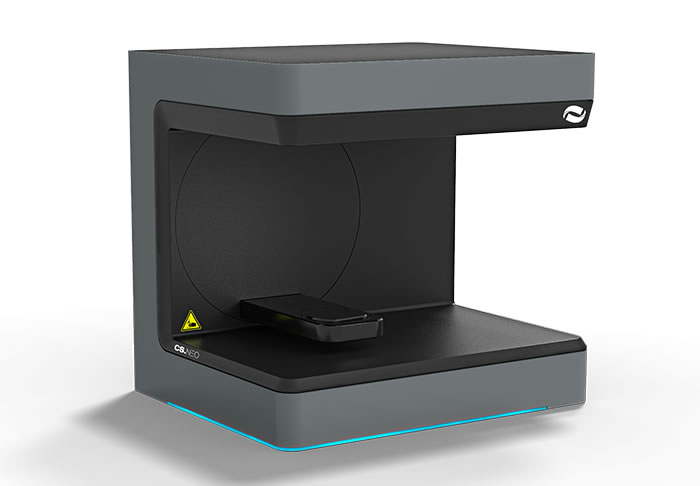

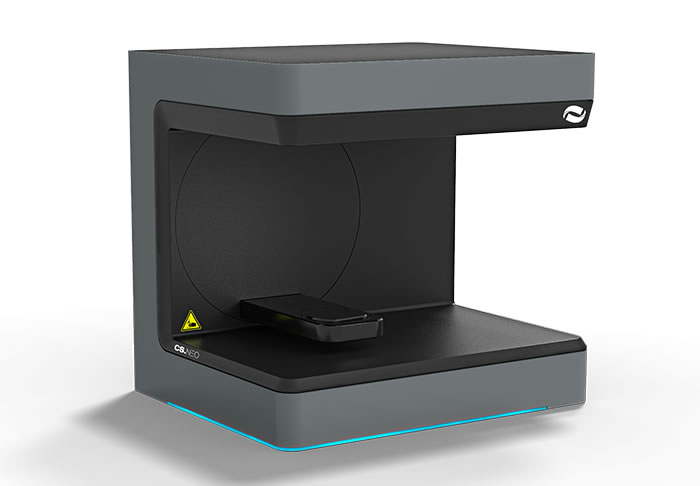

Most current generation scanners on the market use what is called “structured light” – a light projected onto the scan object and captured by on-board cameras. A very few still use a laser light. While there’s been some debate over the years as to which technology is “better” the market has moved to structured light systems because it allows the scanning to occur in an open space as opposed to a closed one, making usage more practical – all without compromising scan quality. Structured light systems project either a blue or white light. Some companies try to market blue light as beneficial over white light, but any real difference between the two is highly debated.

ACCURACY:

Current scanners will scan to an accuracy level of between 4 and 15 microns. Generally the more accurate a scanner is the more expensive it is as the components required to achieve greater accuracy are more expensive. For day to day crown and bridge manufacturing requirements an accuracy level of 10 microns is acceptable. Greater levels of accuracy are desirable when scanning implant cases or doing full arch, interconnected restorations. Some manufacturers focus on the number of megapixels of the cameras in the scanner as a source of accuracy, but this is only partially true. More megapixels will definitely result in more data being captured but this may not result in the acquisition of useful information, and will always slow down the scanning process. Scanners with cameras in the 1.5 to 2.0 megapixel range will produce highly accurate scans in the 4-5 micron range.

SPEED:

Scanners are all relatively fast these days. Like with automobiles, the more you pay for a scanner the faster it goes. That being said, the speed differences from the lower end to the high end amounts to only a few seconds, and speed ratings are generally presented in an unrealistic way. What is usually specified is the speed when scanning using a “light” scanning strategy which generates rougher scan data. The fact remains that when you’re scanning for detail and accuracy the process takes longer no matter what scanner you use. In the end scanner speed is one of the least important factors to consider.

CAPACITIES:

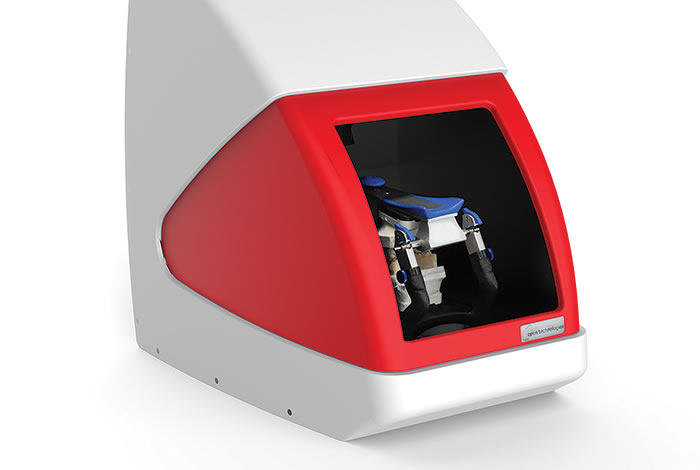

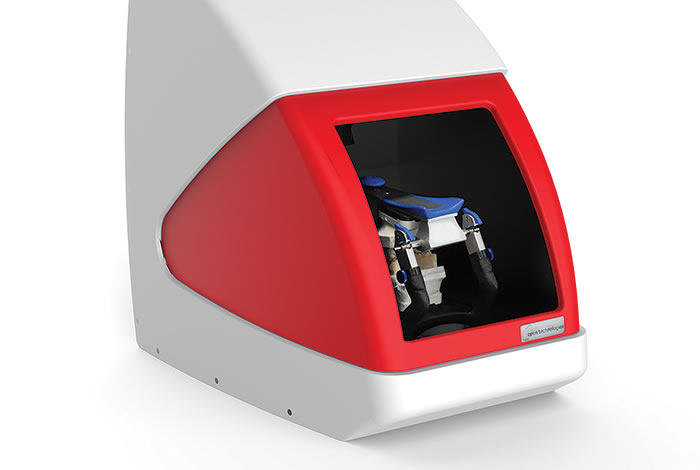

Scanners will vary in what they can actually scan. For example, only some scanners can easily scan a full size semi-adjustable articulator. Only some will scan in colour. Only some are capable of more accurately scanning impressions. Only some have add-ons that the permit transferring specific articulator settings into the CAD software. When selecting a scanner ensure that you’ve fully evaluated the capacities of the scanner beyond standard processes.

BUILD QUALITY, WARRANTIES AND SUPPORT:

Like with virtually all goods, the build quality of a scanner can have an impact on its’ durability and longevity. The better scanners are built with better quality components that will ensure more reliable performance over time. Standard warranties for scanners are typically one year, but two years and more is also common. Finally, support is as important for a scanner as any other piece of digital technology equipment, so ensure that your scanner supplier has the experience and resources to quickly address any issues you face.

TYPE OF INTEGRATION WITH CAD:

In principal the scanner/scanner software and the CAD are two separate things, but many manufacturers don’t treat them that way. All scanners come with software that has the capacity to create projects, manage the scanning workflows and manage the performance of the scanner. At the same time CAD software is usually needed for designing. The software that manages the scanner and the software for CAD are technically separate and independent of each other, however there are two approaches to this.

Some solutions providers make the two types of processes fully interdependent so that you can’t use one without the other. They’ll also typically make the CAD part of the same, effectively closed, ecosystem. In effect they sell a scanner and a CAD solution, together. 3Shape, Dental Wings and In-Lab are examples of such systems.

The exception is exocad CAD, which stands completely independent from the scanner hardware and software. Exocad only sells the CAD. Exocad works with a wide range of scanner manufacturers and those manufacturers work with exocad to have the overall workflows validated so that exocad and scanner “X” work together seamlessly. In the end the CAD and scanner will work in 100% independently of each other. This has advantages in a couple of instances. For one, if you decide that you want to change your scanner you can simply do so without having to change your exocad CAD. In some cases you may simply want to scan something and not be held to the standard “wizard-like” scan processes that the CAD calls for. With an independent scanner you can work completely outside of exocad. It also creates advantages when it comes to annual fees (see below).

SOFTWARE FUNCTIONALITY:

Taking into account the nuances listed above there can be differences in the functionality of the scanner software. Some will allow you more control over scanner performance and scanning strategies, effectively allowing a greater level of customization of the scanner. Some scanner software will give you greater ability to work in non-standard workflows or even create your own; for example when gathering data on completed dentures for the purpose of collecting more complete patient records.

SCAN FILE TYPE:

When initially acquiring data scanners generate the scan data in native or proprietary formats in what is called a “point cloud”. Once scanning is completed the data is “meshed” and it’s at this stage that the scan data can become more or less usable by a user outside of the specific scanner/CAD workflow. Closed systems, like 3Shape, will move the meshed data in a proprietary format. Any scanner working with exocad CAD will allow the user to “mesh” the data using open formats like stl, ply or obj. The most important take-sway here is that if you choose a closed workflow system be sure that the system still allows you to export scan data in an “open” file format like the three just mentioned (.stl, .ply and .obj.) so that the scan data can be used and accessed by your manufacturing partners. They may charge you extra for this ability.

ANNUAL LICENSE FEES:

Annual license fees for the scanner and scanner software are easy to avoid. All you need to do is purchase a scanner that works with exocad CAD. All of the primary scanner suppliers in Canada that work with exocad have no annual fees for the scanner or the scanner software. If you purchase a 3Shape, Dental Wings or In-Lab, because the scanner and the CAD are one package, you’re MANDATORY annual fees apply to both the scanner portion and the CAD portion. The downside of this is that if you decide not to pay the fees your scanner stops working, not just the CAD software. Exocad has two options for their CAD software packages and with one of them annual license fees are optional.

COST:

Scanner prices are very stable at this point in their evolution. Trying to strip out the price of the scanner only is of course challenging with 3Shape, In-Lab and Dental Wings because their systems are sold as a “scanner and CAD” solution, and it’s extremely rare for them to sell their CAD only. The author has never seen these manufacturers sell the scanner only. If you are thinking of buying only a scanner (with scanner software) then you can expect to pay between $7,000 and $18,000. Unless you only need a scanner to add to scanning capacity then you’ll also need CAD software. Once again, valuing the CAD can get tricky depending on what solution you opt for. In any case you’re total cost of investment for a scanner and CAD solution will range from $14,000 to $35,000.

As you can see there are quite a few variables to consider when choosing a lab scanner. This means that defining the “best” scanner is essentially impossible because any choice is a trade-off. Make sure to choose a solution that best fits your overall needs. This way you get the scanner that is “best” for you, as defined by you.