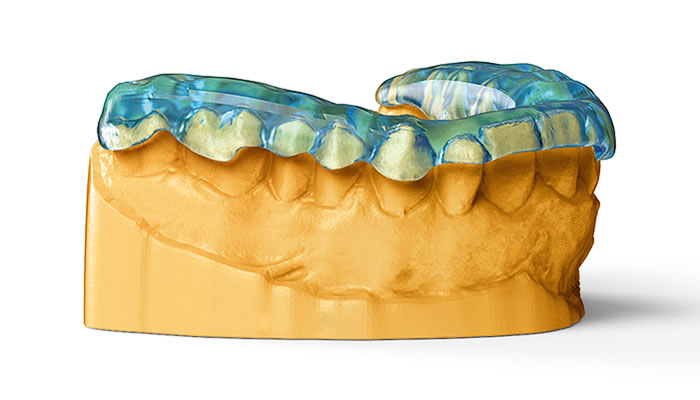

The range of dental materials, advanced print technology and compatibility with leading dental software is transforming dental workflows, enabling dental labs and clinics to produce trays, models, surgical guides, dentures, orthodontic splints, crowns and bridges with enhanced speed, precision and efficiency and lower cost.

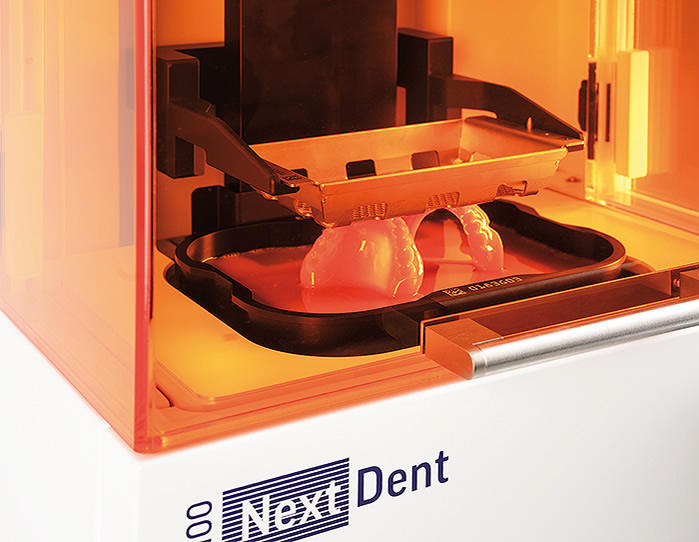

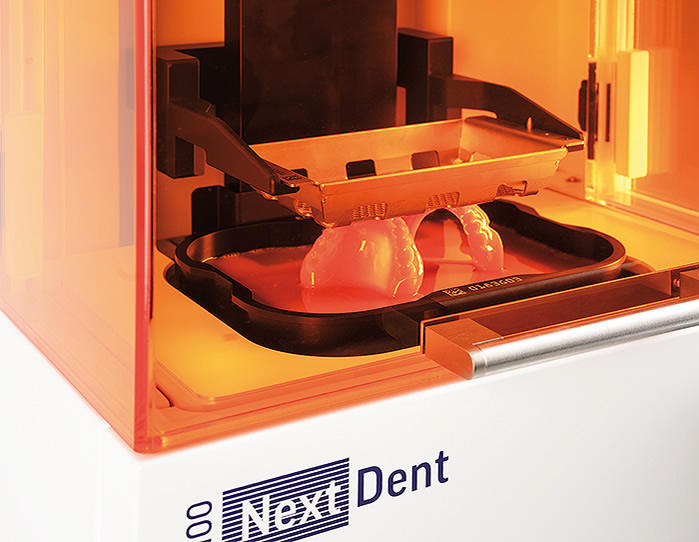

High-speed Dental 3D Printer

High-speed dental solution addressing the broadest range of applications with NextDent biocompatible materials.

Powered by revolutionary Figure 4™ 3D printing technology, the NextDent 5100, combined with the industry’s broadest portfolio of dental materials, addresses multiple applications, resulting in unparalleled accuracy, repeatability, productivity, and total cost of operation.

REVOLUTIONIZE YOUR BUSINESS

The NexDent 5100 3D Printer powered by revolutionary Figure 4TM technology combined with NextDent’s broad portfolio of dental materials addresses multiple indications, resulting in unparalleled speed, accuracy, repeatability, productivity, and total cost of operation.

The NextDent 5100 facilitates high-speed 3D printing for production of dental appliances and sacrificial castings. This revolutionary solution features an industry-defining value proposition that combines best-in-class speed and performance at a price point that is accessible to virtually all labs and clinics.

Trusted End to End Workflow

SOFTWARE

The Nextdent 5100 printing system was developed to make the complete printing workflow process fast, easy and predictable. The intuitive 3D Sprint software allows users to quickly nest and support print objects, and it has powerful standard functions that increase efficiency like automatic mesh repair and the ability to hollow models. Print strategies are partially pre-set and partially selectable by the user, creating a simplified process that results in an unmatched combination of ease of use and predictable print outcomes.

PRINTING

The 5100 printer hardware uses innovative technology that results in incredibly fast print times while preserving precision and accuracy. The printer touchpad interface facilitates the simple and predictable workflow, and ensures that operator errors are kept to a minimum.

POST-PROCESSING

Final dimensional accuracy and stability is dependent on effective post-curing of the printed objects. The Nextdent LC-Cure light curing unit is an affordable and powerful machine that emits two light frequencies, ensuring complete polymerization of the printed objects and the intended physical properties and dimensions.

(All three elements listed above work together to make printing fast, easy, accurate, and above all else, predictable.)

EXPERIENCE YOU CAN COUNT ON

3D Systems has leveraged its 30 years of 3D printing experience in combination with the leading developer of biocompatible dental 3D printing materials to deliver the NextDent 5100 solution. This complete solution represents industry- defining materials and print innovation, dental domain expertise, and regulatory compliance in all major markets to revolutionize your workflow.

LC-3DPRINT BOX UV POST-CURING UNIT

Post-curing is required in order to obtain the final material properties, and is a necessary step to pro- duce a biocompatible end-product with NextDent materials. The lC-3DPrint Box is a revolutionary UV light box equipped with 12 UV light bulbs strategi- cally placed inside to ensure a product is illumi- nated from all sides, which results in a quick and uniform curing cycle.

LC-3DMIXER

The lC-3DMixer keeps your NextDent 3D materials ready for use at any time at an optimum consistency. The lC-3DMixer is a roller/tilting stirring device for mixing 3D printing materials before pouring in the resin tray of the printer. Print resins must be mixed well, and handshaking is insufficient for highly filled and colored materials, and when mixed insufficiently color deviation and print failures may occur.